Sell Your Specialized Electronics & PCB Assembly Business | Specialized M&A & Valuation

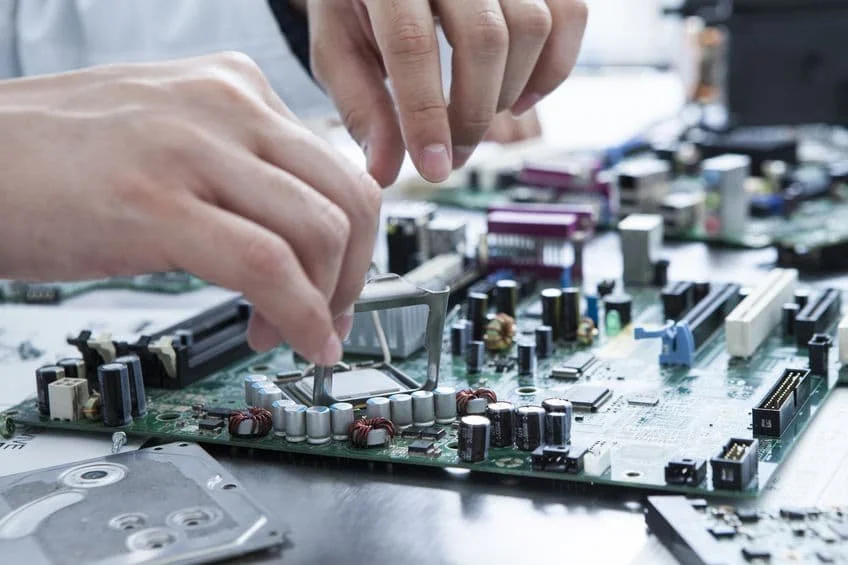

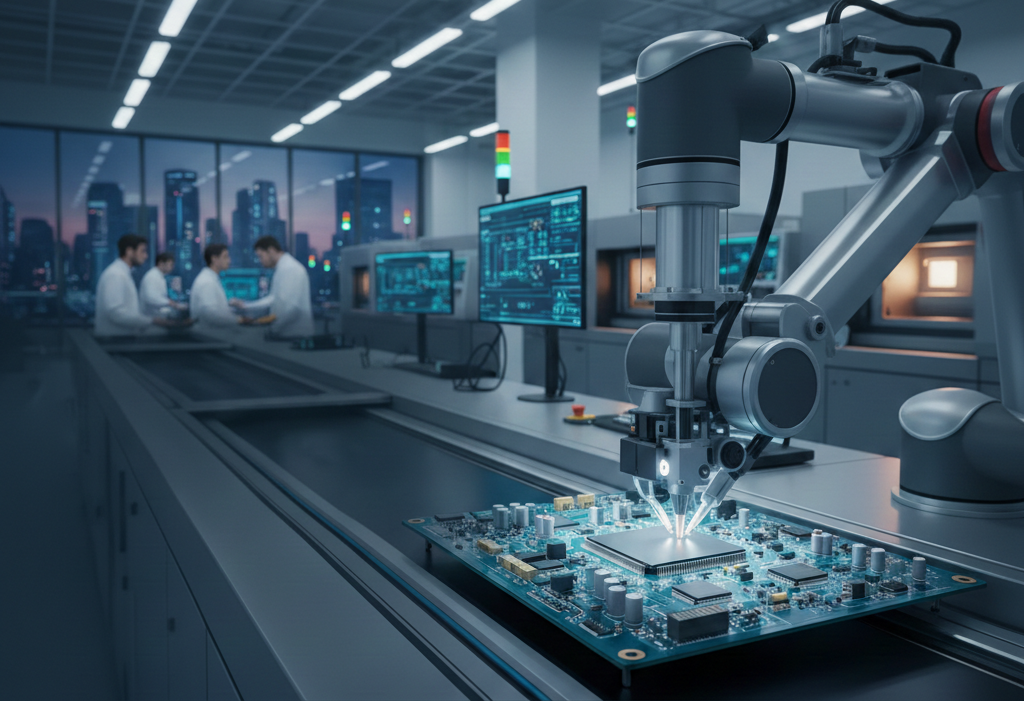

Your SMT lines and engineering talent are more than just line items; they are the foundation of your company's enterprise value. At The Precision Firm, we provide the technical M&A expertise required to translate your complex operational "moats" into the highest possible exit multiple.

The 2025 M&A Landscape for Specialized Electronics

Generalist brokers often fail to appreciate the difference between a commodity assembly shop and a high-reliability (Hi-Rel) PCBA powerhouse. In the current market, buyers are not just looking at your bottom line; they are acquiring your technical capabilities, your certifications, and your seat on long-term programs.

Diversified Blue-Chip Backlog: Buyers are paying a premium for firms with non-concentrated revenue streams across recession-resistant sectors like Medical, Defense, and Aerospace.

Technological Moats: Ownership of specialized processes, such as conformal coating, underfill, or advanced "Box Build" integration, adds significant weight to the valuation.

Supply Chain Resilience: In a post-shortage economy, electronics firms with robust inventory management systems and Tier 1 vendor relationships command superior multiples.

Technical Competencies We Represent in Specialized Electronics

High-Reliability (Hi-Rel) PCB Assembly

Focus Area: Mission-critical electronics for Aerospace, Defense, and Space applications.

Icon Suggestion: A schematic overlay of a satellite or a fighter jet circuit board.

Equipment & Labor: Multi-stage SMT lines, Automated Optical Inspection (AOI), X-Ray inspection for BGA integrity, and IPC-certified soldering technicians.

The Buyer Pool: Strategic Tier 1 defense contractors and Private Equity firms focused on "GovCon" roll-ups.

Key Certification: AS9100D and NADCAP.

Medical Device Electronics (MedTech)

Focus Area: PCBA for life-saving diagnostic equipment, implantables, and surgical robotics.

Icon Suggestion: A stylized EKG pulse integrated with a circuit trace.

Equipment & Labor: Cleanroom assembly environments (ISO Class 7 or 8), Flying Probe Testers, and specialized quality assurance auditors.

The Buyer Pool: Global medical device OEMs and specialized life-science investment groups.

Key Certification: ISO 13485.

Advanced Micro-Electronics & HMLV

Focus Area: High-Mix Low-Volume (HMLV) production for industrial IoT, telecommunications, and high-end consumer tech.

Icon Suggestion: A high-density microprocessor chip with intricate gold-wire bonding.

Equipment & Labor: High-speed pick-and-place machines, Selective Soldering, and NPI (New Product Introduction) engineering teams.

The Buyer Pool: Regional strategic competitors looking to expand their technical footprint or "platform" PE investors.

Key Certification: IPC-A-610 Class 2 and 3.

Navigating Industry-Specific Compliance in M&A

ITAR and EAR Export Controls

The Problem: International Traffic in Arms Regulations (ITAR) compliance is a massive hurdle for non-domestic buyers. An unorganized compliance history can lead to massive fines or the total collapse of a deal during the Committee on Foreign Investment in the United States (CFIUS) review.

The Solution: The Precision Firm conducts a "Pre-Flight" compliance audit, ensuring all registrations are current and that "Technical Data" access is strictly controlled, making the business "Due-Diligence Ready" for domestic aerospace buyers.

IPC-A-610 Class 3 Standards

The Problem: Maintaining the highest level of workmanship for life-support or mission-critical systems is expensive. Buyers often underestimate the labor costs and training required to maintain these standards, leading to "valuation gaps."

The Solution: We quantify the "Hard-to-Replicate" nature of your certified workforce, framing your Class 3 compliance as a competitive barrier that justifies a higher EBITDA multiple than Class 2 shops.

Tier 1 Supplier Re-Certification Risk

The Problem: A change in ownership can trigger "Change of Control" clauses in major contracts, requiring the new owner to go through a rigorous re-certification process with the OEM.

The Solution: We proactively manage the communication strategy with your Top 5 customers, ensuring that the transition of ownership is framed as an infusion of capital and stability rather than a risk to their supply chain.

How We Value a Specialized Electronics Business

The "Technical Premium" is a definition of the added value found in electronics firms that possess specialized equipment and certifications that a generalist job shop lacks. These firms command higher multiples because they operate in high-margin, high-barrier-to-entry niches.

Barrier to Entry (CAPEX): The high cost of modern SMT lines and specialized testing equipment prevents new competitors from entering the market, protecting your margins.

Recurring Contract Revenue: Unlike "bid-to-bid" shops, firms with "Program Wins" on long-term platforms (e.g., a 10-year defense contract) provide the predictable cash flow that Private Equity seeks.

Intellectual Property & Fixturing: Your proprietary test fixtures, custom code for AOI/Flying Probe, and specialized process "recipes" are intangible assets that we capitalize during the valuation process.

Frequently Asked Questions: Selling a Specialized Electronics Business

-

A: Specialized electronics businesses are valued at a premium over general manufacturing because of their higher technical barriers to entry and specialized CAPEX requirements. While a general machine shop might trade at 4x to 5x EBITDA, a high-reliability PCBA firm with medical or defense contracts can often command 6x to 8x+ EBITDA.

-

A: Certifications like AS9100 or IPC-A-610 Class 3 significantly increase enterprise value by de-risking the business for Tier 1 aerospace and defense buyers. These certifications act as a "license to operate" in high-margin sectors, making the firm a more attractive acquisition target for strategic buyers.

-

A: Contract backlog is treated as a primary indicator of future cash flow stability and is often used to justify the upper bound of an EBITDA multiple during the normalization process. A strong backlog demonstrates to a buyer that the revenue is "sticky" and not dependent on the owner’s personal relationships.

-

A: Customer relationships are protected through a phased disclosure process where sensitive contract details are only revealed during deep-stage due diligence under strict Clean Room protocols. We ensure that your customers only learn of the sale after the deal is finalized or at a point where the transition is guaranteed to be seamless.

-

A: A typical industrial M&A exit for a specialized electronics firm takes between 6 to 10 months from the initial valuation to the final wire transfer. This timeline includes the preparation of the Confidential Information Memorandum (CIM), the marketing phase, the Letter of Intent (LOI) negotiations, and the final 60-90 day due diligence period.

Ready to Maximize the Value of Your Specialized Electronics Business?

Selling a technical business requires an advisor who knows the difference between a reflow oven and a wave solder machine. At The Precision Firm, we are former operators and engineers who have sat on your side of the table.

We don't just "list" businesses; we engineer exits that reflect the true value of your technical expertise and specialized asset base.