Sell Your Medical Device Manufacturing Business | Specialized M&A & Valuation

Selling a medical device manufacturing firm requires an advisor who understands that your value isn't just in your equipment, but in your validated processes and Quality Management System (QMS). We bridge the gap between complex shop-floor operations and high-level financial engineering to ensure you capture the full "Technical Premium" of your enterprise.

The 2025 M&A Landscape for Medical Device Manufacturing

In today's market, generalist brokers fail to account for the immense CAPEX and regulatory "moats" that protect medical device shops. As OEMs (Original Equipment Manufacturers) continue to consolidate their supply chains, they are aggressively acquiring Tier 1 and Tier 2 suppliers that possess niche technical capabilities and impeccable compliance records.

Validated Process Longevity: Buyers are paying a premium for "locked-in" processes where IQ/OQ/PQ (Installation, Operational, and Performance Qualification) have been established for long-term FDA-approved programs.

High-Margin Material Proficiency: Expertise in machining exotic biocompatible materials like PEEK, Titanium, and Nitinol creates a barrier to entry that justifies a higher EBITDA multiple.

Customer Concentration Mitigation: Modern strategic buyers look for firms with deep "stickiness" within the medical community, where the cost of a customer switching to a new supplier is prohibitively high due to re-validation requirements.

Technical Competencies We Represent in Medical Device Manufacturing

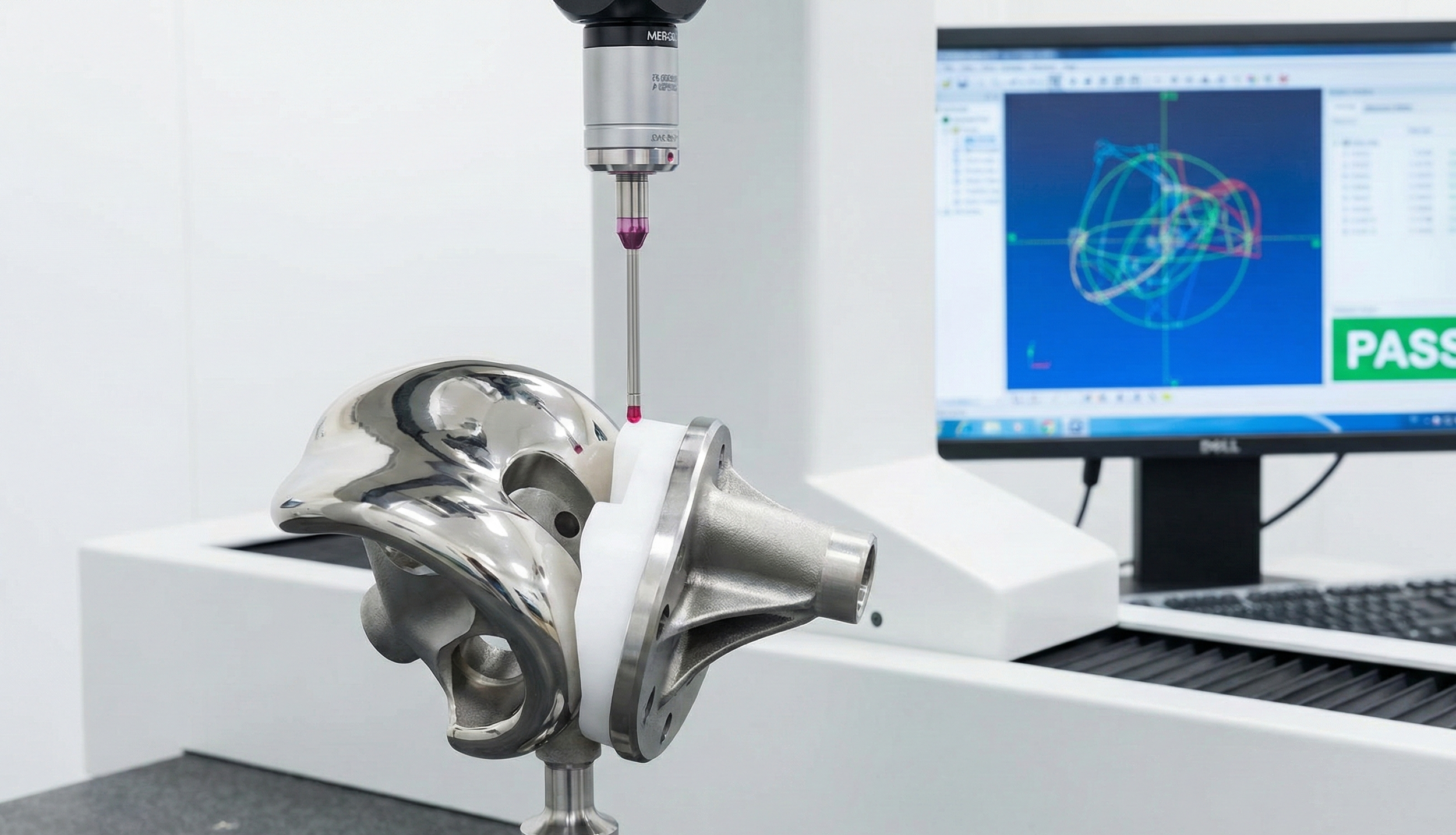

Orthopedic & Spinal Implant Manufacturing

Focus Area: High-tolerance machining of complex geometries for bone screws, plates, and joint replacement components.

Icon Suggestion: A technical blueprint of a titanium spinal cage with multi-axis toolpath indicators.

Equipment & Labor: 5-axis CNC machining centers (Matsuura, DMG Mori), Wire EDM, and Red-Badge machinists specializing in tight-tolerance finishing.

The Buyer Pool: Global Orthopedic OEMs and Private Equity "Buy-and-Build" platforms focused on musculoskeletal health.

Key Certification: ISO 13485:2016 and FDA Registered Facility status.

Precision Vascular & Catheter Components

Focus Area: Micro-machining and extrusion of ultra-small components used in minimally invasive surgical procedures.

Icon Suggestion: A microscopic view of a laser-cut stent or catheter tip.

Equipment & Labor: Citizen and Star Swiss Lathes, Laser Ablation systems, and Cleanroom assembly technicians (Class 7 and 8).

The Buyer Pool: Strategic MedTech conglomerates and Tier 1 cardiovascular suppliers seeking to vertically integrate.

Key Certification: ISO 14644 (Cleanroom Standards) and ISO 13485.

Surgical Instrumentation & Robotics

Focus Area: Production of reusable and disposable instruments for robotic-assisted surgery (RAS) platforms.

Icon Suggestion: A high-precision robotic arm gripper or surgical tool assembly.

Equipment & Labor: Multi-axis mill-turn centers, automated polishing systems, and ASQ Certified Quality Engineers (CQE).

The Buyer Pool: High-growth surgical robotics companies and specialized contract manufacturing organizations (CMOs).

Key Certification: ISO 13485 and experience with Part 820 Quality System Regulation (QSR).

Navigating Industry-Specific Compliance in M&A

FDA 21 CFR Part 820 & Quality System Regulation (QSR)

The Problem: During due diligence, institutional buyers will conduct a "deep dive" into your Device Master Records (DMR) and Design History Files (DHF). If these are not audit-ready, it can lead to a significant "valuation haircut" or even the collapse of the deal due to perceived regulatory risk.

The Solution: The Precision Firm performs a pre-sale "Gap Analysis" of your quality records. We ensure your QMS is presented as a turnkey asset, proving to the buyer that the transition will not trigger FDA scrutiny or corrective actions.

IQ/OQ/PQ Validation Protocols

The Problem: A buyer's technical team will assess the validity of your equipment qualifications. Unvalidated machines or outdated protocols suggest that the revenue generated from those assets is at risk if an OEM customer demands a re-validation.

The Solution: We highlight the depth of your validation backlog as an intangible asset. By documenting the rigorous Installation, Operational, and Performance Qualifications already in place, we justify a higher "Moat" value in the final purchase price.

Supplier Risk Management & Traceability

The Problem: In the medical sector, supply chain transparency is non-negotiable. If your raw material traceability (Heat Lot tracking) is manual or disorganized, it creates "unquantifiable risk" for the buyer’s compliance team.

The Solution: We showcase your ERP integration and automated traceability systems as a "Scalability Driver." By proving that your compliance is tech-enabled, we position your firm as a low-risk, high-efficiency acquisition target.

How We Value a Medical Device Manufacturing Business

A medical device shop is not a "job shop." It is a technical ecosystem that commands a Technical Premium. While a general machine shop might trade at 4x to 6x EBITDA, a validated ISO 13485 firm often trades at 7x to 10x+, depending on the depth of the technical "moat."

Regulatory Barrier to Entry: The 2-3 year lead time required for a new competitor to achieve ISO 13485 certification and FDA registration provides a protected "cash flow runway" that buyers pay to occupy.

High Switching Costs: In the medical industry, the "cost of change" for an OEM is massive due to the need for re-testing and regulatory filings. This results in highly predictable, recurring revenue streams from long-term contracts.

Asset Intensity and Validation: The combination of advanced CNC CAPEX and the "software" of the validated process creates an asset base that is nearly impossible to replicate quickly, driving up the enterprise value.

Frequently Asked Questions: Selling a Medical Device Manufacturing Business

-

A: Medical device businesses are valued at a significant premium over general manufacturing, often commanding EBITDA multiples 20% to 50% higher due to stringent regulatory barriers and high OEM switching costs. This premium is driven by the "locked-in" nature of the contracts and the high level of technical expertise required to operate.

-

A: ISO 13485 certification acts as a baseline requirement for institutional buyers; however, a "clean" audit trail and mature QMS can increase the enterprise value by demonstrating reduced post-acquisition risk. Firms without this certification are often viewed as "turnaround" plays and face significant valuation discounts.

-

A: Contract backlog is treated as a primary indicator of future revenue stability and is often used to justify "pro-forma" EBITDA adjustments during the due diligence phase. A strong backlog of $5M+ in a $20M revenue company provides the buyer with the confidence to offer a higher multiple.

-

A: Customer relationships are protected through a "blind" marketing process and "no-contact" periods until the final stages of due diligence to ensure zero disruption to the supply chain. We use highly redacted CIMs (Confidential Information Memorandums) to ensure your competitors and customers remain unaware of the sale until it is strategically appropriate.

-

A: The typical timeline for a medical manufacturing exit is 6 to 9 months, accounting for the specialized Quality of Earnings (QofE) review and regulatory document verification required by strategic buyers. This timeframe allows for a competitive bidding process among several qualified buyers.

Ready to Maximize the Value of Your ISO 13485 Medical Device Manufacturing Business?

At The Precision Firm, we aren't just bankers; we are former operators. We know the difference between a Swiss lathe and a machining center, and we understand why a "clean" ISO audit is a major financial asset. We specialize in positioning technical businesses to attract the highest-quality strategic and private equity buyers globally.

Don't leave your life's work to a generalist who doesn't understand your "moat." Let’s discuss your 2026 exit strategy today.